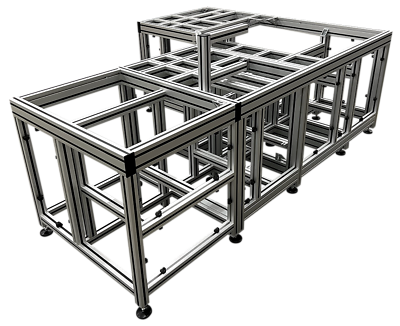

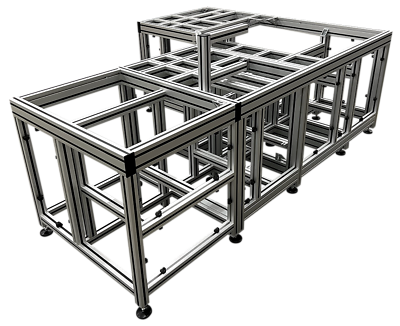

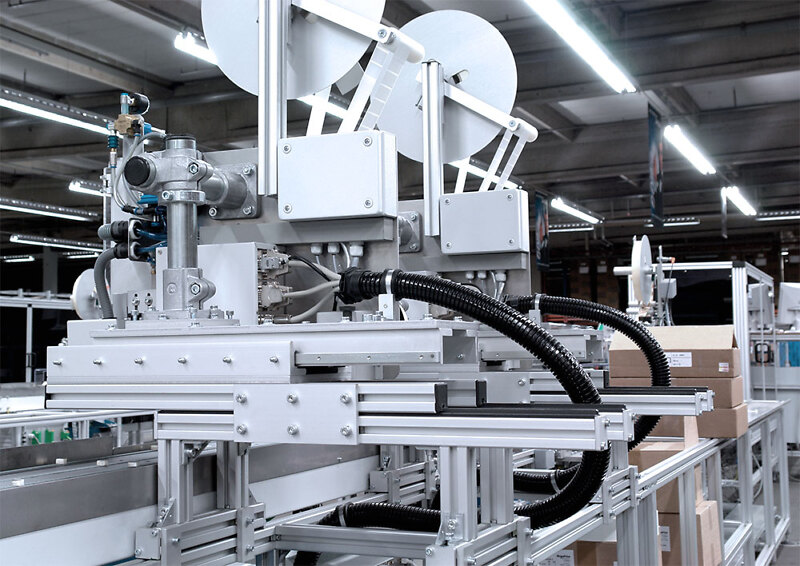

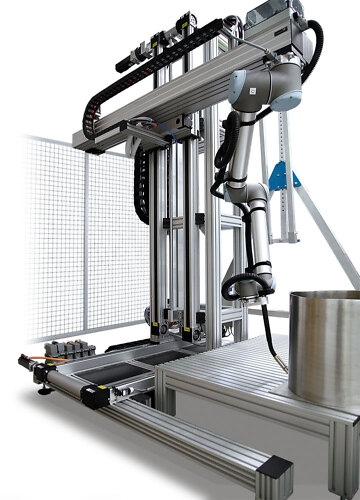

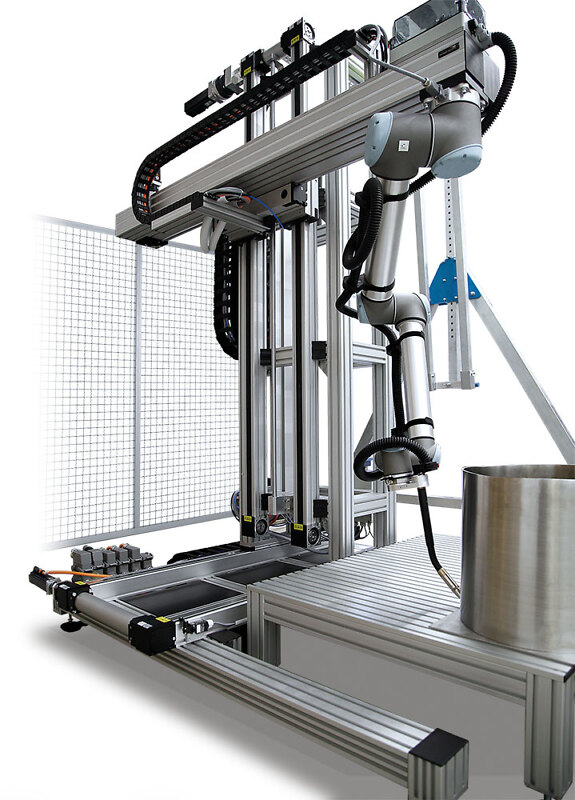

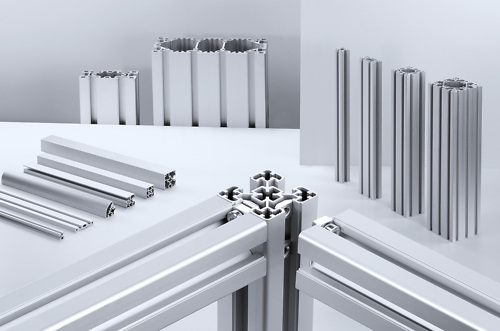

Individual machine frames from quantity 1

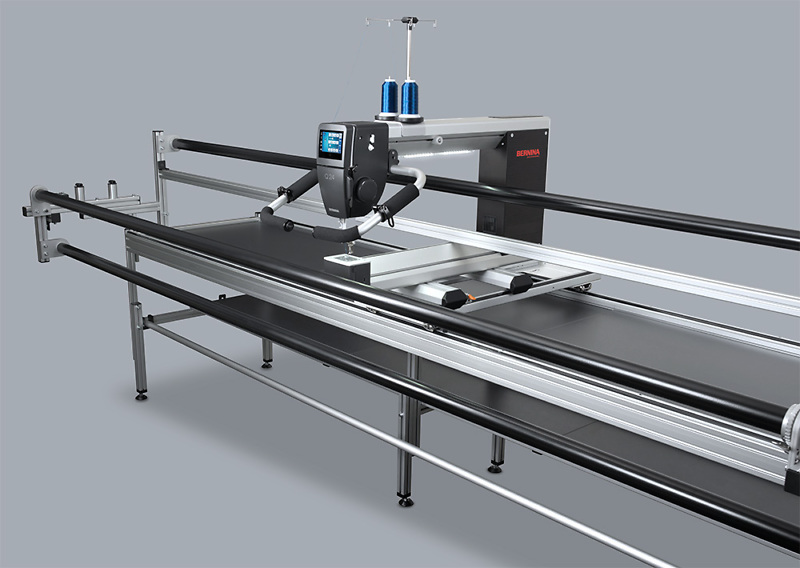

We supply machine frames, machine frames and special constructions from quantity 1 up to large series. The design and dimensioning of our basic frames made of aluminum profiles depends on the respective process task and the required accuracy of the machine concerned. Constructions made of aluminum profiles are a stable and flexible alternative to welded constructions, even in the heavy load range. The size of the profiles used is based on the loads that occur. Thus, technically correctly designed profile constructions are an economical solution. Decisive advantages of our machine frames: They are light, yet stable and so flexible that they can be adapted to changing process conditions at any time.