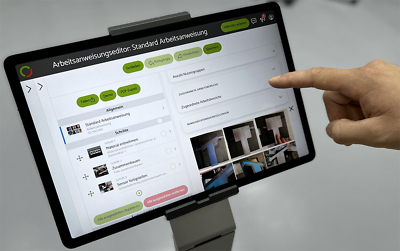

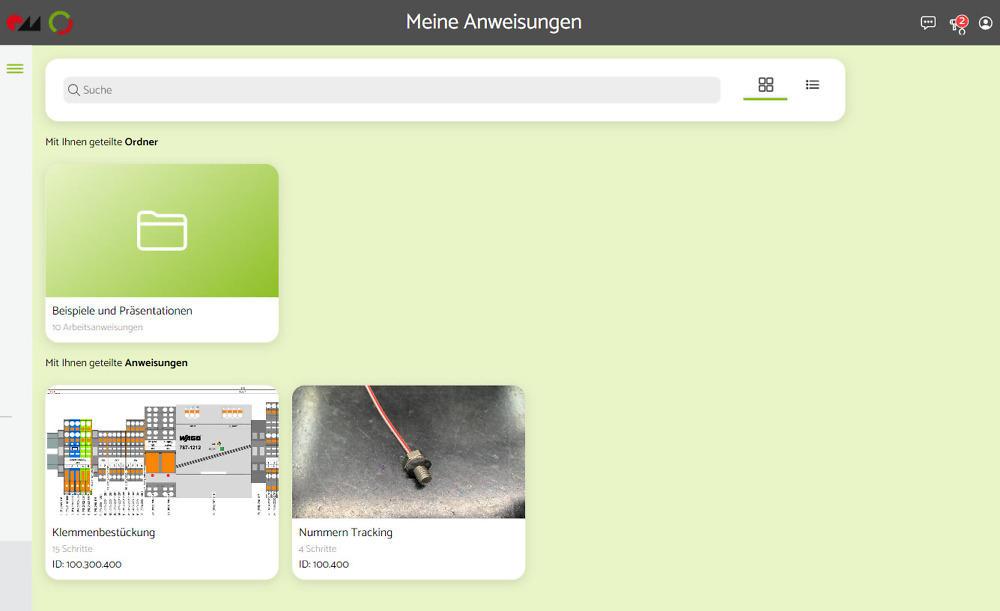

Overview of work instructions

All recorded instructions can be clearly grouped and arranged. A preview image supports identification.

Search function

Text field to search for the desired work instruction. Finding and selecting can also be done by scanning a barcode

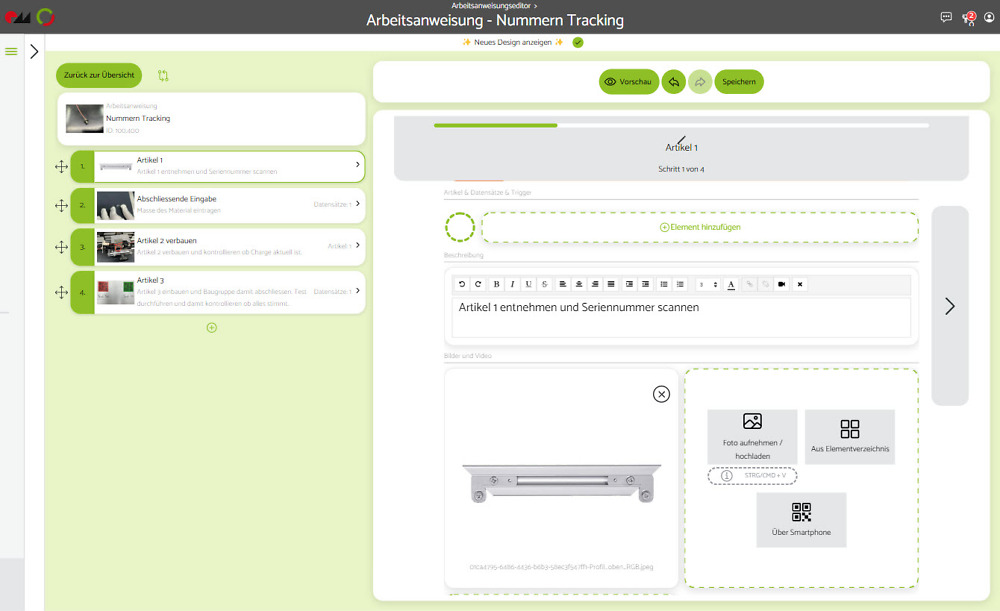

Work instruction preview

Overview of the work instruction. Preview image, article number, title and the number of work steps

Display / View

A tile and list view are available for selection

Folder structure

Create folders to better group and structure work instructions