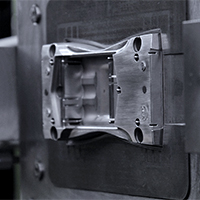

For whom do we supply profile housings?

Whether innovative start-ups or companies excellently established on the market ‒ anyone who needs aluminum extruded profiles or extruded plastic profiles for their electronics depends on good professional support. The focus is not only on the design of the enclosures. Important details such as service life, hygienic properties, ease of assembly and a reasonable price have a strong impact on the end product and its success on the market.

We accompany our customers in the complete process around extrusion resp. extrusion from the idea to the serial production of your end product incl. assembly and shipping. Just ask our product specialist for detailed expert advice on your ideas. We step in with our expertise exactly where it makes sense and is desired for your project.