Services and project procedure

From the idea to the machine housing

Idea / concept

Idea / concept

Send a sketch, CAD data, or we will visit you on site and establish your requirements

Engineering

Engineering

CAD design with all technical features and preparation of the parts list. Approval by the client

Manufacturing

Manufacturing

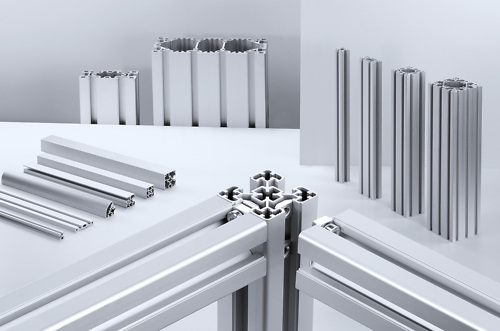

Special painting, cutting of surface elements and profiles, production of special parts and adapter plates

Assembly

Assembly

Building of the complete assembly at our premises. Acceptance by the client when required

Assembly on site

Assembly on site

Delivery of the assembly. On-site assembly upon customer request

Your machine layout and your requirements define the framework conditions – we take over the detailed planning of the optimum machine enclosure! Your wishes and the layout of your machine determine our approach to the realization of standard-compliant machine enclosures. Basically, almost anything is possible!

If you know exactly what you want and provide us with concrete drawing specifications, we will implement these for you. We would even rather develop the optimum enclosure for your machine together with you. For this purpose, our specialists discuss all machine details, functions and processes with you on site and advise you on the necessary functional details such as maintenance access, doors, material bulkheads, etc.. Subsequently, we take over the drawing for you, manufacture the complete machine casing, assemble it for acceptance by you on site and take care of the entire logistics.