Pick by Light worker guidance for zero errors in production

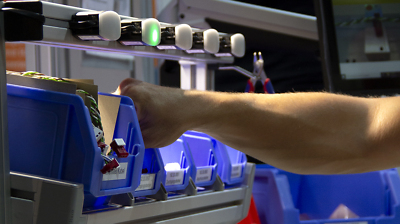

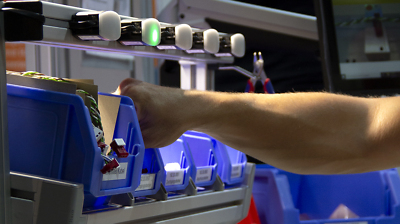

The SETAGO® Pick by Light worker guidance system is based on the worker assistance software, which guides employees step by step through the assembly process using images and videos. In addition, the Pick by Light worker guidance system includes sensors that indicate which component needs to be picked and where. This ensures error-free execution of the assembly process throughout.

The operation is very simple: The SETAGO® system uses digital work instructions to show the worker which component to assemble next, where to take it from and how to assemble the component. Correctly executed workflows initiate the next process step. If the worker accidentally picks up the wrong material or uses the wrong torque for tightening, this is recognised and the assembly process is stopped. Continuation is only possible after correction. This eliminates errors, ensures product quality and increases productivity.

At the same time, with the support of SETAGO® Pick-by-Light, even new, inexperienced or cognitively impaired employees can fulfil complex orders reliably and productively with practically no training time.

Pick by Light reduces assembly errors by 99.9% and ensures continuous quality

Increases productivity by up to 50%

Employees require hardly any training time and are immediately productive and can therefore quickly help out in unfamiliar assembly processes in the event of breakdowns or high workloads

The light sensor shows the employee where the part to be mounted is located

Prevents mixing up components that look similar

SETAGO® Pick-by-Light provides an interface to several, optional ERP systems