Swiss Lean Award 2023

Phoenix Mecano Solutions AG wins the Swiss Lean Award 2023, a national certificate that recognises outstanding achievements in the field of lean management.

New Product

Learn more

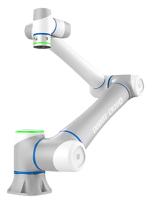

Cobots from Dobot

The cobots are known for their flexibility, ease of control and wireless networking capability, making them ideal for a wide range of applications. A highlight of the product range is the SafeSkin technology, an innovative accessory that enables early collision detection and therefore increases safety in the workplace.

New Product

Learn more

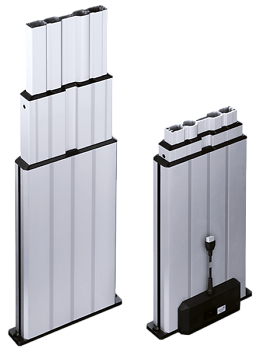

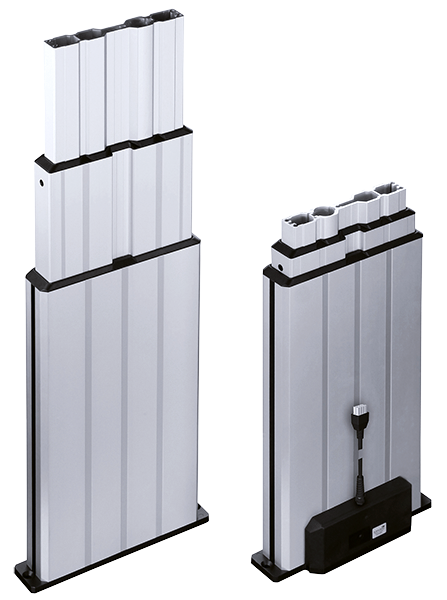

HMI operating panel SL5000

Modern operating panel with 4 profile depths starting from 40mm, which can be additionally combined with each other. Glass surfaces with bonded touch screens and displays can be installed in the front in addition to standard machine controls. The rear panel is either screwed or hinged.