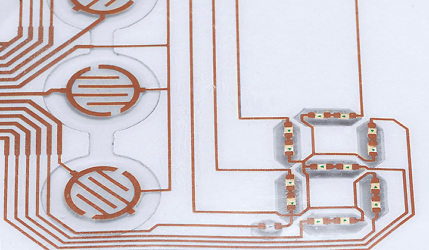

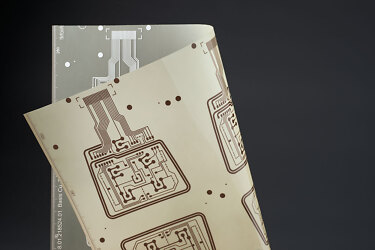

Membrane keypads with copper conductors

For optimum functionality and durability, we exclusively produce high-quality membrane keypads based on refined copper conductor tracks. This technology offers extremely high electrical and mechanical reliability as well as low conductor track resistance. Even complex electronic circuits can be directly integrated into the keypad and automatically assembled using SMD technology. Another advantage of this technology is that the foil connection cable can be bent with very small radii without the risk of breaking the conductor paths. This can be the decisive advantage over conventional conductive silver technology, especially when space in the housing is tight.