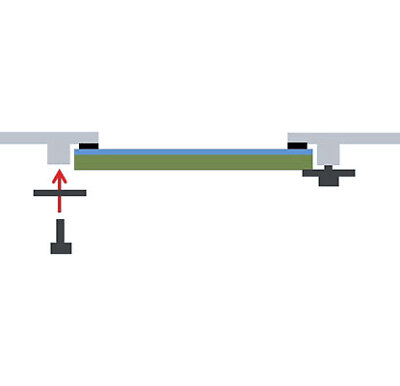

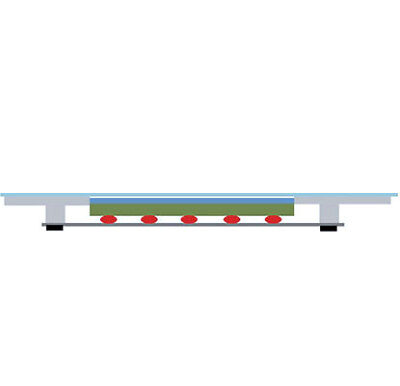

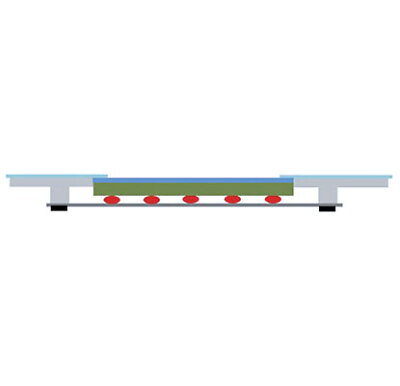

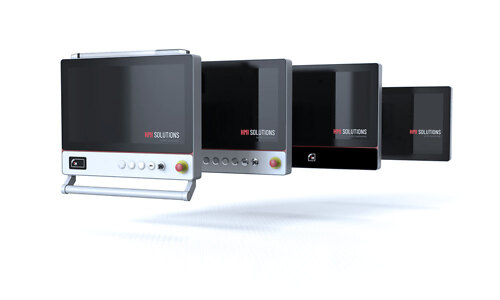

Possibilities of display and touchscreen integration

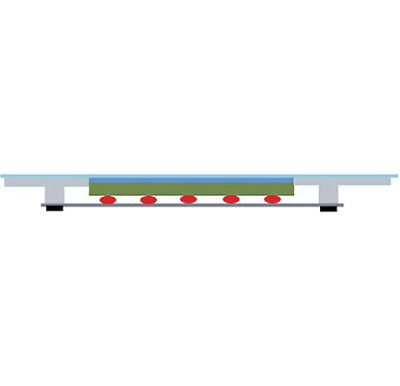

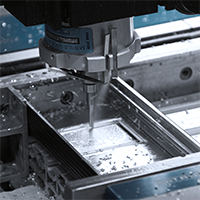

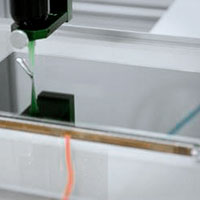

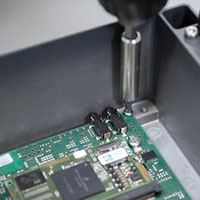

Touchscreens and large displays are also gaining ground in industrial machine and plant control. The big problem with touchscreens and displays is that they are not standardized parts. Each display looks different, has different mounting options and different dimensions. This makes installation in a front or a housing not easy. We rely here on different installation options, which differ greatly in appearance, technical features and price.