Swiss Lean Award 2023

Phoenix Mecano Solutions AG wins the Swiss Lean Award 2023, a national certificate that recognises outstanding achievements in the field of lean management.

New Product

Learn more

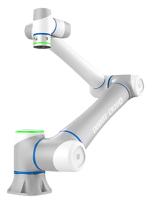

Cobots from Dobot

The cobots are known for their flexibility, ease of control and wireless networking capability, making them ideal for a wide range of applications. A highlight of the product range is the SafeSkin technology, an innovative accessory that enables early collision detection and therefore increases safety in the workplace.

New Product

Learn more

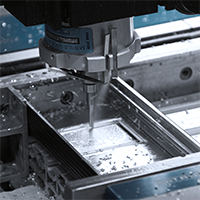

Production data acquisition (PDA) - The easiest start to paperless production

The production data acquisition system controls and documents the entire production process on the shop floor. The PDA system is not only convincing due to its possible e-paper connection. As quickly implemented, simple and cost-effective software, it is the ideal solution for industrial SMEs.